Purchase Orders

Distribute - 2017

Purchase orders are the backbone of wholesale, yet somehow this process was completely inefficient. Everything was manual, each buyer and supplier did things slightly differently, and it was more common than not that there would be weeks of back and forth before a purchase order was confirmed. Now that we had inventory data and a way for buyers to facilitate orders, it was time for us to tackle purchase orders.

Where to start?

Problem with the current state of wholesale POs:

Process was entirely manual

Information was completely disconnected

Sending POs back and forth multiple times for one order was the norm

Each party had their own rules for purchasing (for both suppliers and buyers)

The biggest problem we uncovered above? That the PO process was different for every company. With this in mind, we began our ideation by breaking down these various processes into their key elements. The hope was that we could piece them together in a better way, creating a more efficient, streamlined process that worked for everyone in the industry.

After combing through everything with my PM, we found that the 5 main components were:

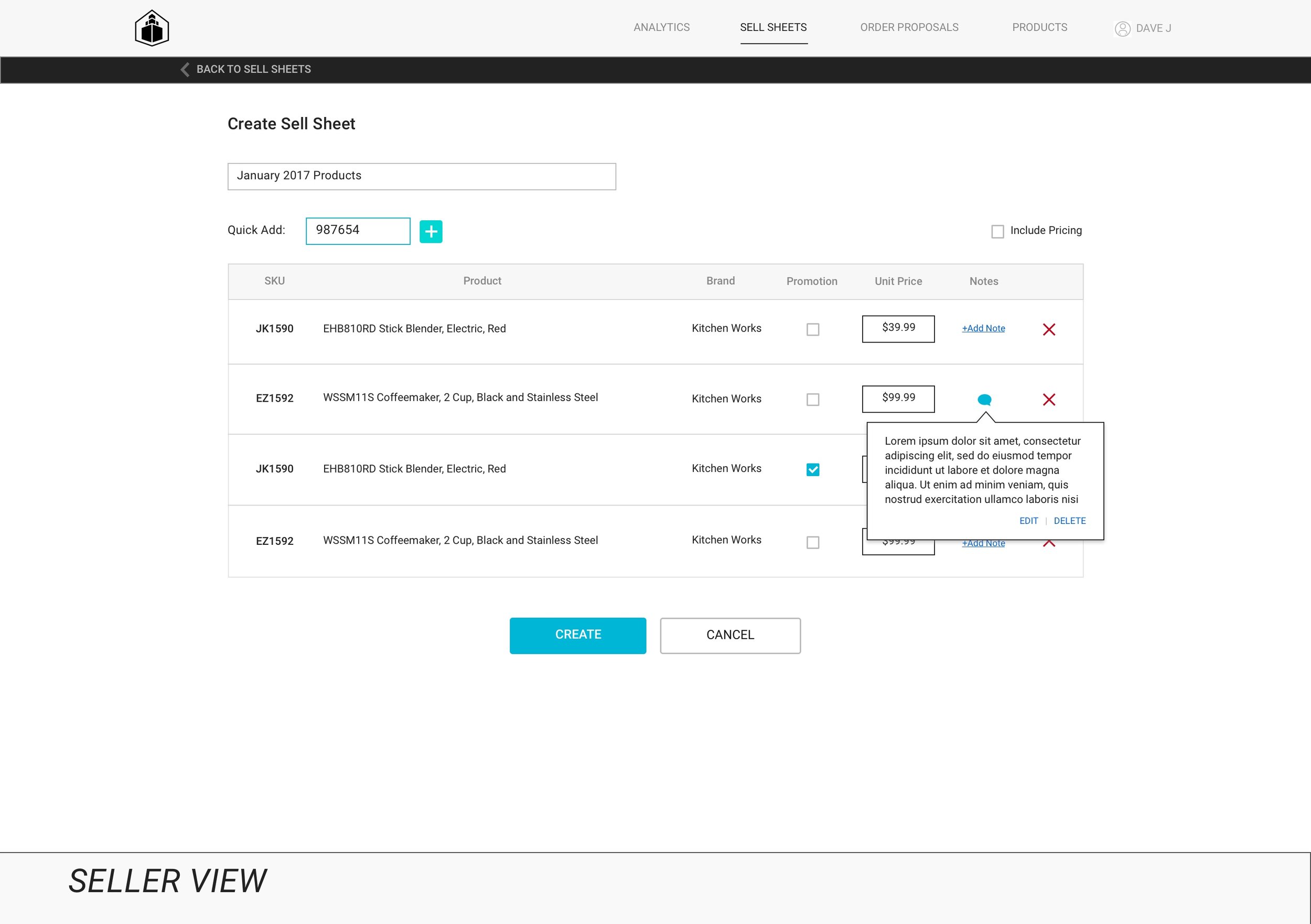

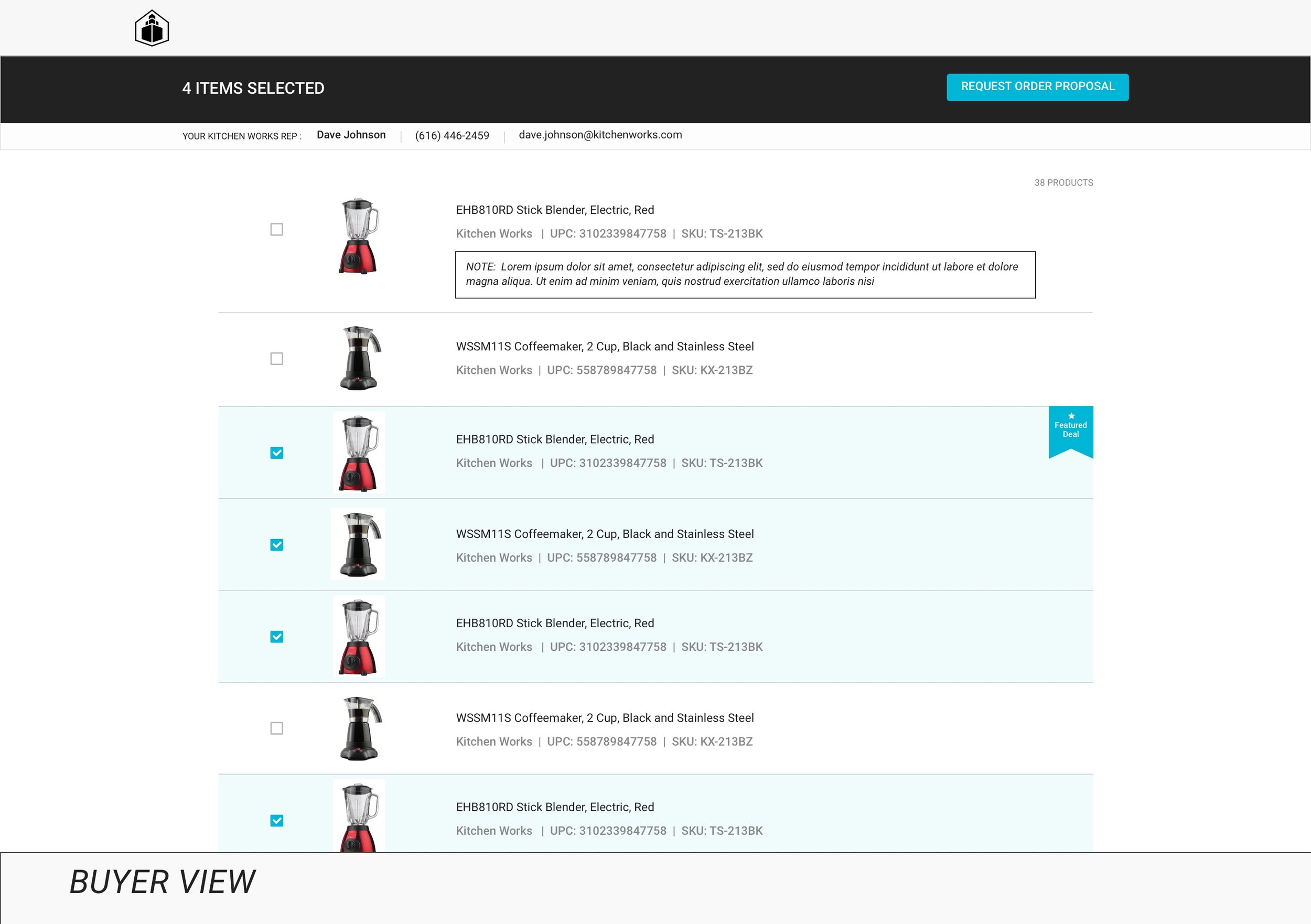

Supplier has a way to get inventory in front of their buyers [DONE — our Sell Sheets tool]

Buyer needs to be able request to purchase supplier inventory [DONE — checkout via Sell Sheets]

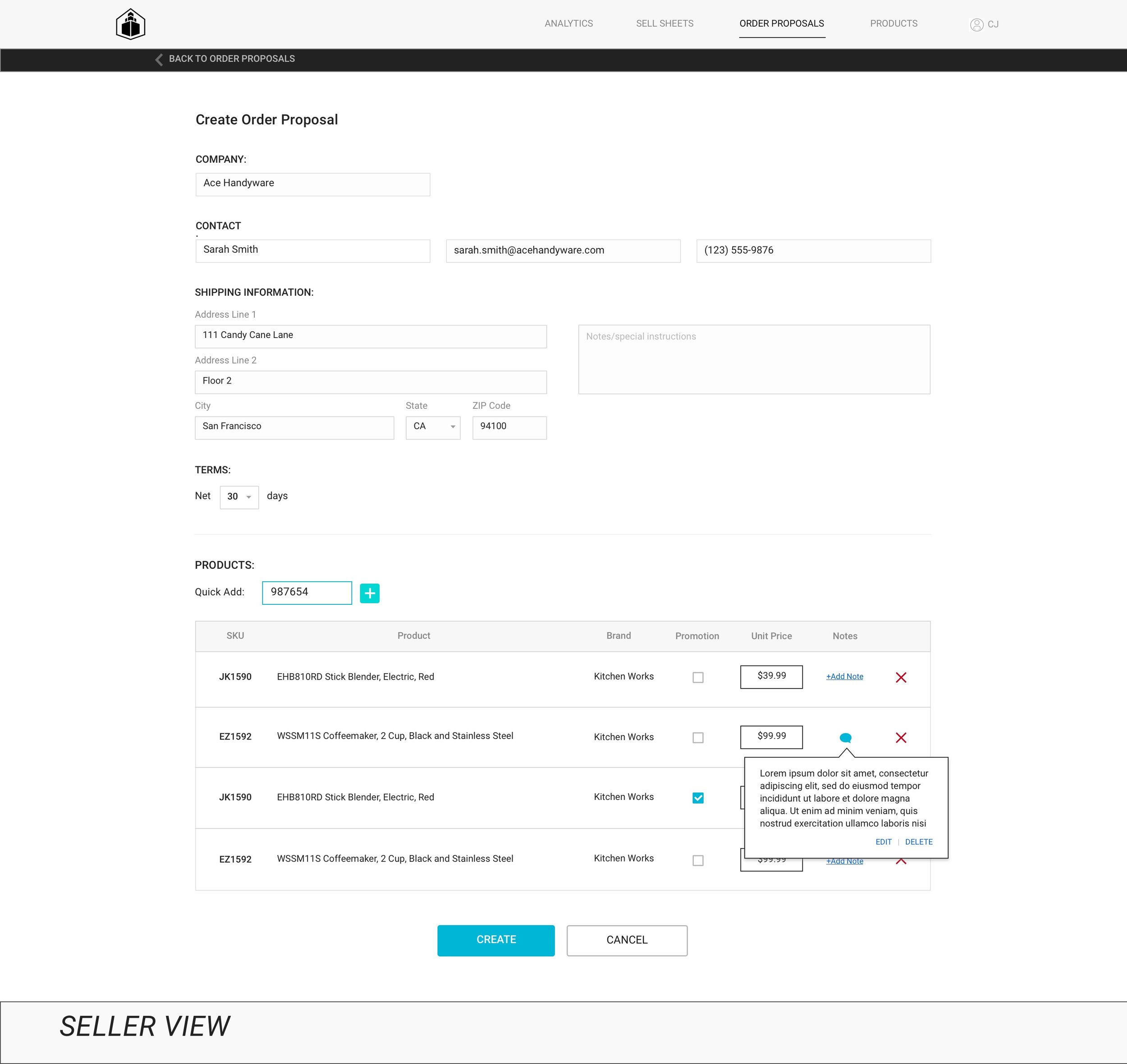

Supplier needs to be able to view/adjust pricing and set terms

Supplier needs to know contact and delivery details

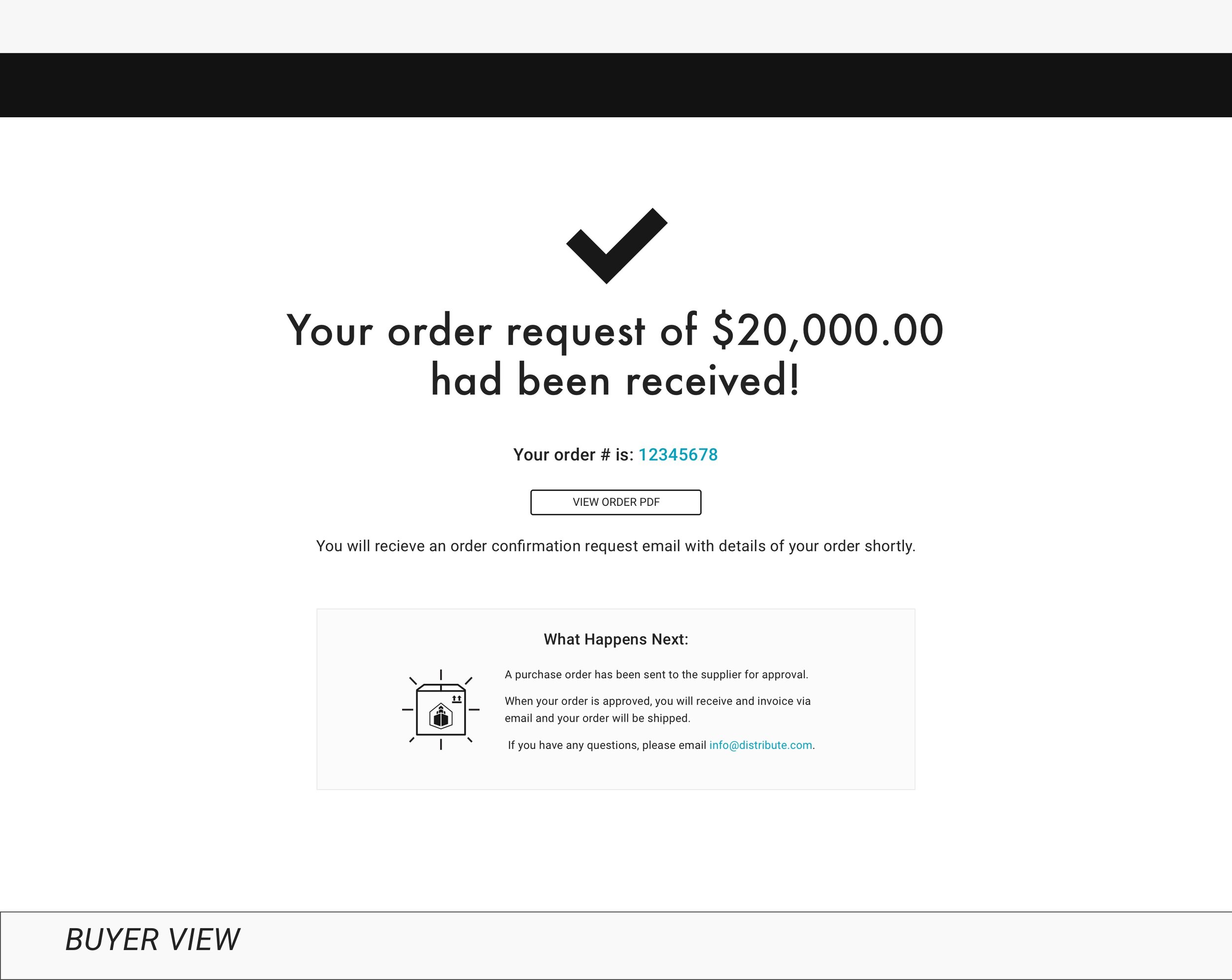

Both buyers and suppliers need to approve of final order

So, how do we measure success?

Main measure:

A buyer and supplier are able to complete an entire purchase order from start to finish via only our platform.

Secondary metrics:

Reduced time from initial PO request → order placed (<2 weeks, can track via date stamps)

Reduced tools used to complete PO process (eliminate need for email/fax/phone calls/external places of record)

Increased understanding into the status of your (supplier/buyer) POs (via interviews - does the user understand where in the process each of his/her orders are?)

Ideation & Prototypes

Version 1:

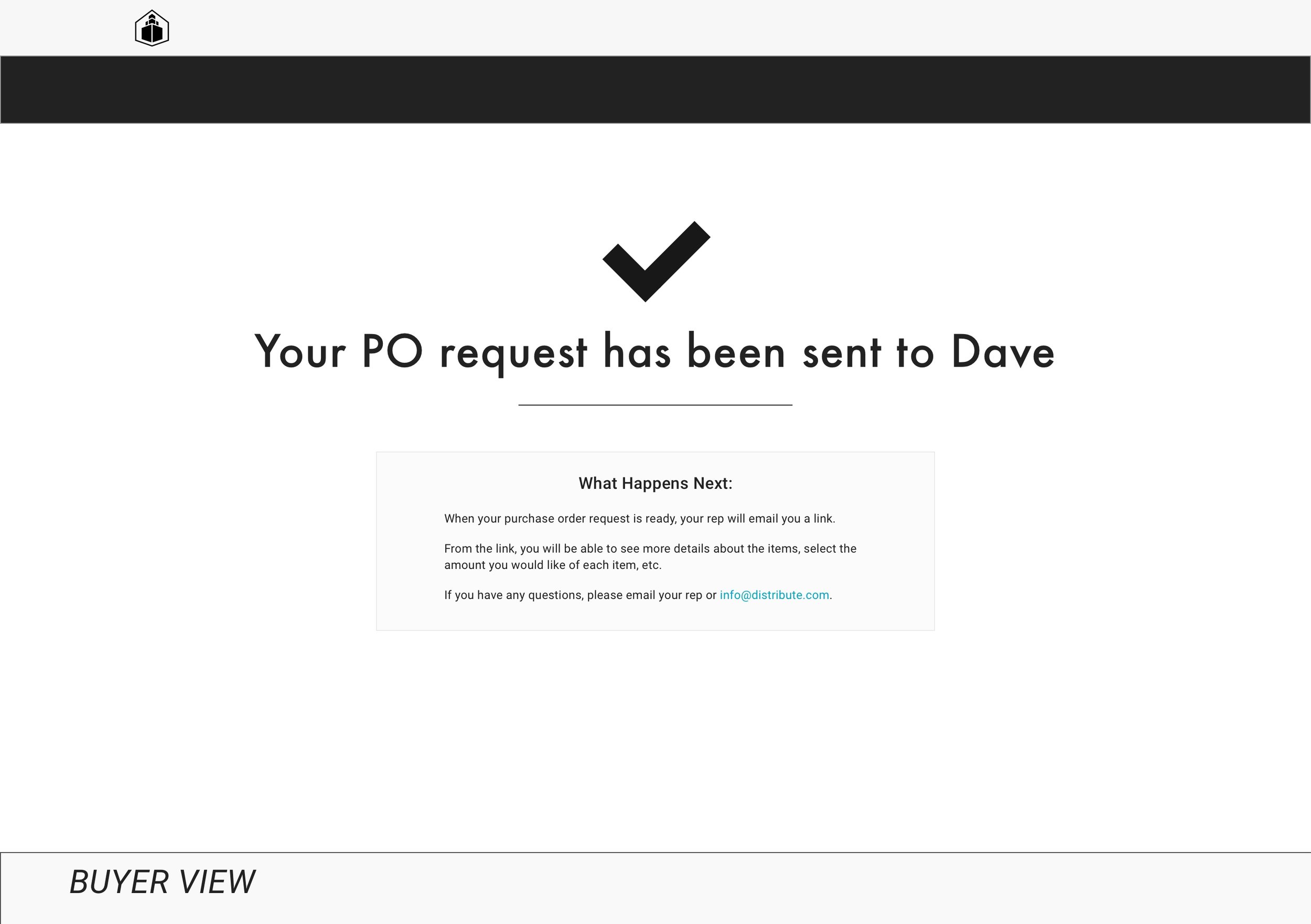

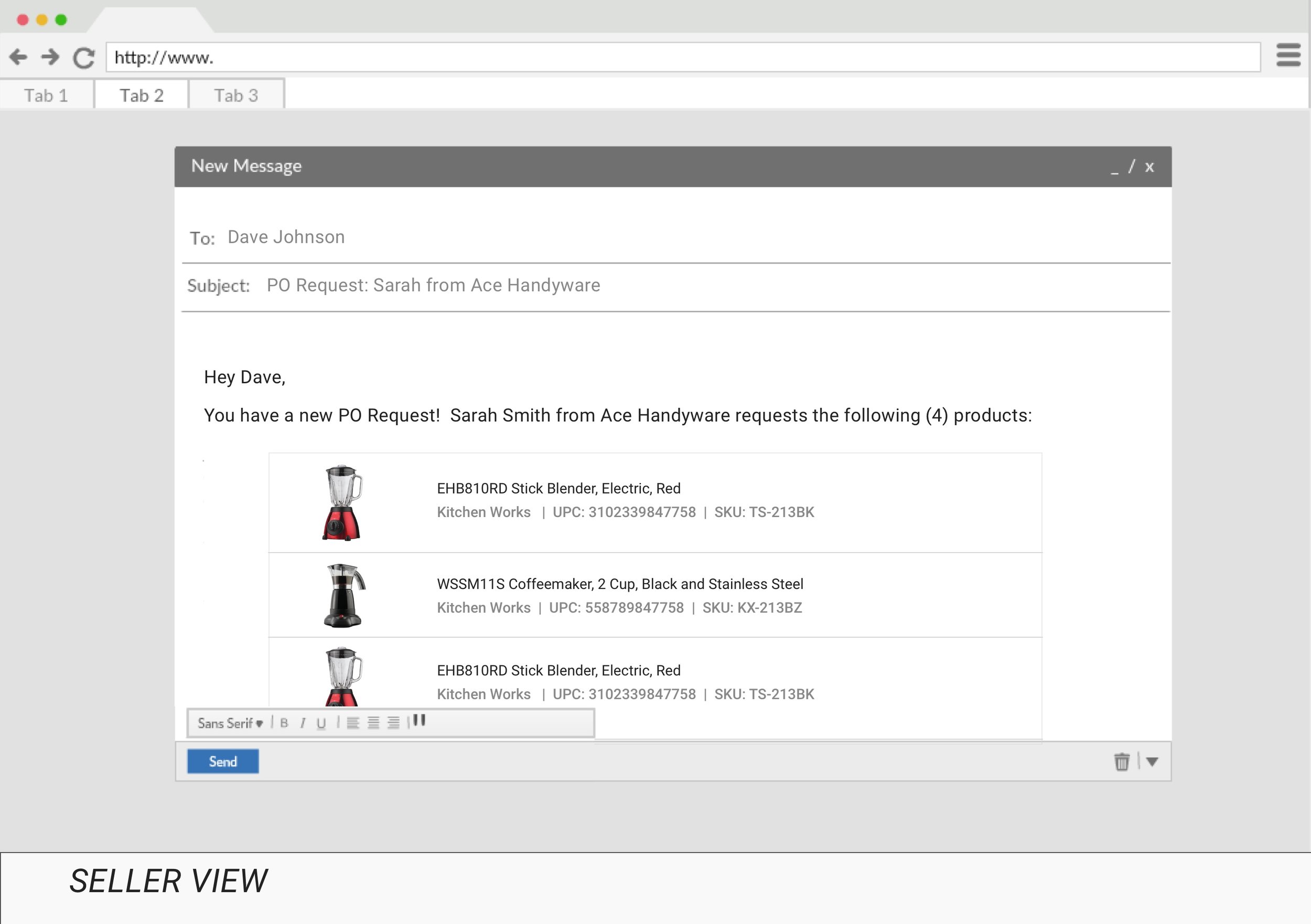

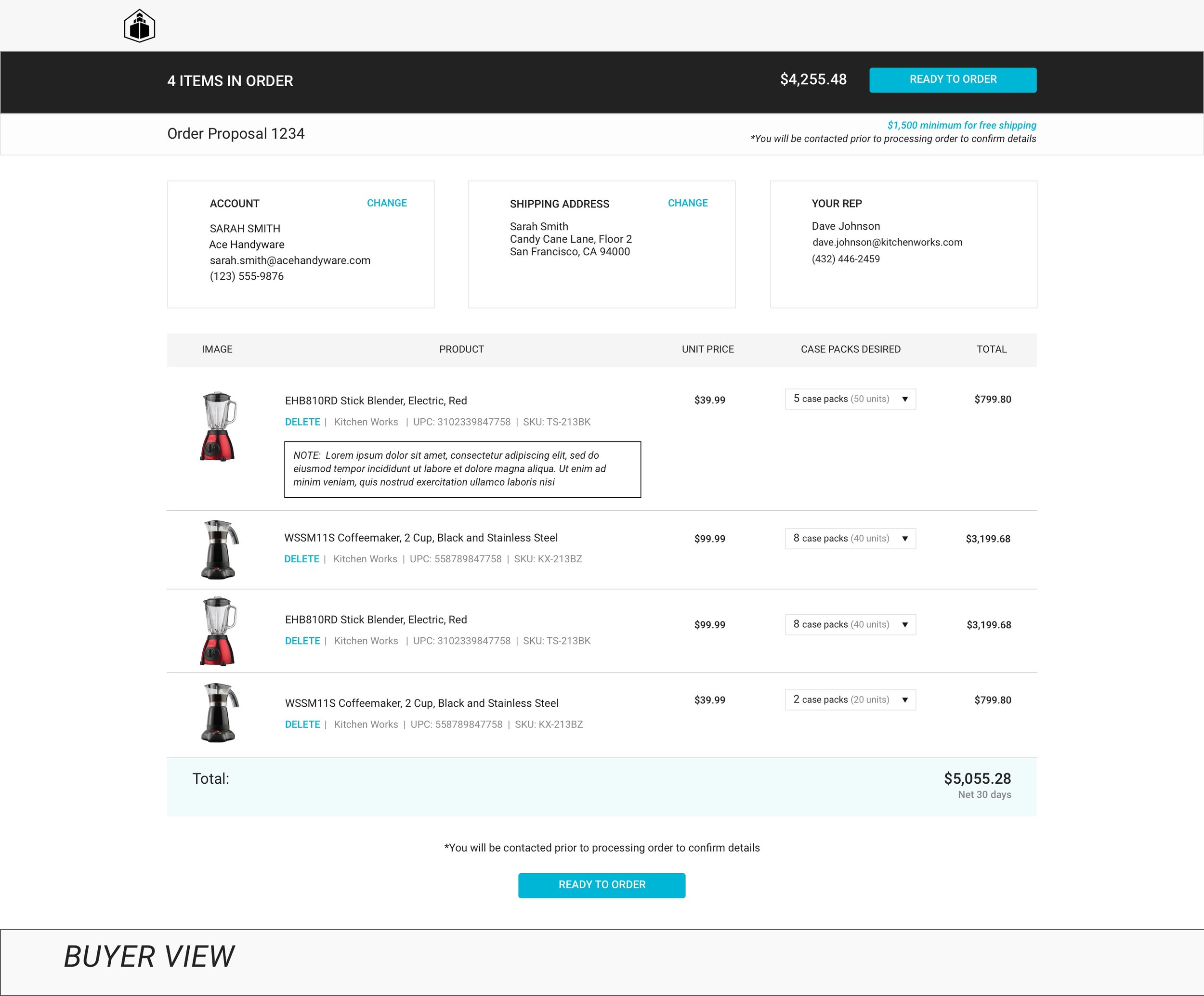

Our first attempt to create a simplified process allowed suppliers to create purchase orders after a buyer requests to purchase inventory via a sell sheet. Once the supplier creates the PO, it is sent to the buyer for final approval. This mimicked much of what happened then manually, but with each step of the process tied together rather than separate.

Though we were close with this version, it didn’t quite hit the mark. Creating POs from requests from buyers put a lot of unnecessary burden on the suppliers, on top of the fact that they didn’t always know key elements like delivery details. Additionally, we were missing permanence. Buyers and suppliers needed to be able to easily understand how many orders they have and the status of these orders. In this version, we missed giving the order a home throughout each part of the process.

Version 2:

This led us to rethink purchase orders. Though purchase orders would go through many iterations, each one was its own entity — just in a different status. Ah-ha! Breaking the process into different order statuses would not only help each side understand was is happening with their orders, but also keep the order present for both parties throughout the process (instead of passing it back and forth like a piece of paper).

We pieced together 4 common states that encompassed the entire process for each side.

This version seemed to make sense when we presented it with the team. Not only did it give more transparency into the process, but set clear expectations for which party needed to do what. In order to confirm this “new world” of purchase orders didn’t miss anything, I created a set of wireframes and demos to present to some of our customers to get their feedback.

Stage 1:

Stage 2:

Stage 3:

Reflection & Improvements

Though we had all of the critical elements in this first version of purchase orders, there were still a few key improvements that we uncovered when getting feedback from our customers.

The first problem we uncovered was that ending the PO statuses on “Order placed” was misleading because orders that were placed didn’t mean that they were fulfilled. This led us to the addition of 2 more statuses: partial and shipped. If part of the order had shipped, but not the full order, it was considered “Partial”. If the entire order was shipped, it was considered “Shipped”. Now buyers and suppliers had better insight into the active status of their placed orders.

During usability testing, we also found that:

It was hard for the supplier to understand which customers had a pricing tier discount

The product section was a bit overcrowded, so it was hard for suppliers to find how to add tracking info

Both buyers or suppliers sometimes required extra information (product specs, shipping documentation, etc)

This lead us to test and implement the following features that we found alleviated these frustrations and need for outside products:

Break out the shipping date from the product section to declutter the product section.

Addition of the assigning buyer pricing tiers that are then called out on the POs, removing the need to look up a buyer’s buying status each time they order.

Added the ability to attach external documents to the order so that all information needed for an order could be found in one place.

The last piece to note that we held off on was the ability for buyers to add notes beyond “special instructions”. Though this feature was asked for to mimic the current state of negotiation, we decided to keep the PO process strictly around POs and eventually add the ability to “message” a seller. This would mean making it a separate process that would allow a more clean back and forth without muddying up the PO. The PO number would be attached so that Distribute would continue to be the place of record for everything order related.